Delivery

Delivery? Delivery is one of our strongest points. With a fully operational fleet and transport department

we can deliver anywhere in South Africa and even up in Africa. That's right, we are not scared of the long road.

We cover the height and width of South Africa Dayly, and can quote to deliver your load anywhere in Africa on Special request.

We have some of the best trained drivers that are dedicated in the business, and your load will be fully insured untill you sign over ownership of the material.

We have the following vehicles in our fleet.

- 2x DAF Horse and trailor - 36 Ton Payload

- 6x DAF Horse and trailor - 24 Ton Payload

- 8x DAF Horse and trailor - 18 Ton Payload

- 10x DAF 9mtr Fix Body - 8 Ton Payload

- 6x DAF 6mtr Fix Body - 8 Ton Payload

- 12x DAF 6mtr Fix Body - 4 Ton Payload

Stockist

We are the largest stainless steel stockest in South Africa and of largest stockists in the Southern Hemisphere.

With a massive stock holding between R350million and R500Million we are sure to satisfy your needs for any project or purchase no matter how big or small.

We replenish our stock with reputable suppliers all over the world between 4-6 times per financial year.

Our suppliers all approved by refinaries not only in South Africa, but also around the world.

We use our massive buying power to get you, the end user the best price as possible to make us competative in the market.

We stock the following items:

- Pipes in Welded and Seamless.

- All pipe fittings in seamless, welded and welded-xrayed.

- All types of flanges in forged or plate.

- All stock standard plate sizes and also cut to size.

- Raw Forgings

- Round Bar

- Hollow Bar

Fittings Manufacturing

We have a fully opporational plant to manufacture pipe fittings and flanges. We are the only manufacture in Africa and South Africa that can manufacture A403 fittings that include Elbows Seamless and Welded from 1/2" to 6". Larger Elbows can be made but only in welded and Welded-xrayed, up to 24". We are the only company in the Southern Hemisphere that has a Tee press. Con Reducers and Ecc Reducers can be pressed and con swages will fall under the same production line. The x-rays on the WP-WX range are all done in house by an independant inspection authority. We do all the heat treatment in house so that the fittings comply to the ASTM and ASME specification.

Forging

We have recently invested a huge amount of money to upgrate our forging department. We have invested in a 5Ton hydraulic Press. We can now forge forgings up to 3 meter in diameter and 1 meter thick. With the proper control on the temprature and the force on the material we can produce top quality forgings. But this press only makes out a part of the rest of the Forge Hammers and the drop forge equipment that we have. We also have a total of 6 furnaces to make sure of a constant flow of work to the forges. We currently put out 30 tons per day from our forge shop. The basic turn around time for forgings are 1-4 weeks depending on the forging and forging process.

Profile and Laser Cutting

Steel Giant use only the best machinery for our Laser cutting. Swiss-manufactured Bystronic 6,5 m x 2,4 m laser cutting machine, which is capable of precision cutting steel plates in thicknesses of up to 25mm (material dependant). Bystronicis recognised as a world-leading supplier of high-quality machines and systems for the economical processing of sheet metal and other flat materials. By ensuring that it makes use of only the best laser cutting machine, Steel Giant provides its clients with the peace-of-mind that they will be provided with the highest standards of accuracy and quality.

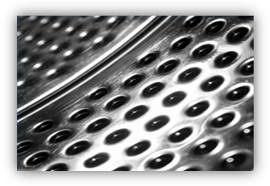

Plate Perforation

A Perforated Plate is manufactured by cold punching sheets of metal, with an arrangement of holes of any shape and size in various patterns. There is a large variety of Perforated Sheets available in different styles. Perforated Sheets and Plates are used in a vast number of industries for sorting and screening any material from Sugar, Maize and Spice to Pharmaceutical, Chemical and Metallurgical. We do various types of patterns in a variety of materials and thicknesses are stocked. The shapes include round (rd), square (sq), round end slot (res), and hexagon (hex). The configurations include straight (strt) and staggered

Ring Rolling

Steel Giant is renowned as a global leader in the manufacture of seamless forged Rings for the rail, petrochemical, civil engineering, power generation and medium to heavy engineering industries. One of the largest forging companies in the southern hemisphere, Steel Giant boasts the most powerful and technologically advanced seamless components manufacturing facility on the African continent. Specifically it is a leading supplier of forged railway tyres for mainline railway, metro trains and trams globally. Other products include high pressure flanges for turbine wind towers and the petrochemical water reticulation industry, rings for bearings, gears and specialist items. Products are manufactured to customer specifications in carbon, alloy and stainless steel. The company operates from a custom-built manufacturing facility with an annual capacity of 80 000 ton. Our facility is equipped with cutting edge equipment imported from leading German and Italian suppliers.

Pipe Rolling

This specification covers electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service, or both, or for general

applications. The pipes shall be sorted into five different classes. Class 1 pipes shall be double welded by processes employing filler metal in all passes and shall be

completely radiographed. Pipes of Class 2 shall be double welded by processes employing filler metal in all passes with no radiography. Both Class 3 and Class 4 pipes shall

be single welded except that the weld pass of the latter exposed to the inside pipe surface may be without the addition of filler metal. Pipes of Class 5 shall be double

welded by processes employing filler metal and shall be spot radiographed. Weld defects shall be repaired by removal to sound metal and rewelding. Subsequent heat treatment

shall be as required on the original welds. The finished pipes shall be subjected to transverse tension test, transverse guided-bend weld test, and hydrostatic test.

Back To Top